WMS, managed warehouse

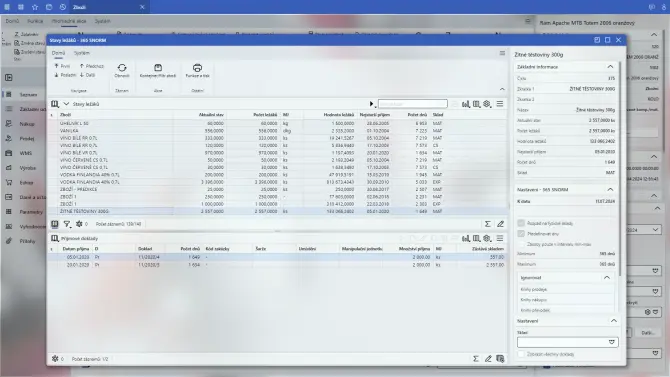

The WMS solution (Warehouse Management System) from K2 takes care of clear and accurate records of all warehouse items and movements. On the so-called product card, you will have basic data such as price, unit, dimensions or weight, as well as more detailed records by batch. Thanks to it, you can easily identify items across the entire system. You will always have a perfect overview of the status and movements in the warehouses.

Many customers think of mobile terminals when they think of WMS. For other companies, there are WMS readers, and artificial intelligence built on top of that. For some, it starts with conveyors, cardexes and robotics or voice guidance for warehouse workers. K2 can solve everything.

Thanks to the automatically controlled warehouse, the error rate will be reduced and the efficiency of the warehouse worker's work will increase. In this way, you can store or ship a larger number of items and the costs of handling the article will be reduced.

Based on historical data, the K2 information system can estimate the necessary stock for the next period. Thanks to this, you can easily predict how much and what you will need in the future and adjust the amount of stock accordingly. With the correct settings, the system is even able to minimize so-called dead stocks. This can save your company up to millions of crowns per year.

Any change made on the reader will be reflected in the system. And it works the same way the other way around – when someone makes a payment, receipt or order – everything is automatically reflected in the WMS. On the article card, you can see the movements of individual pieces of goods or the complete movements of a lot.

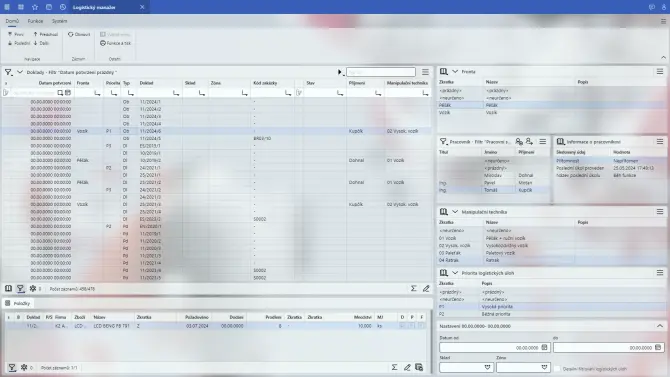

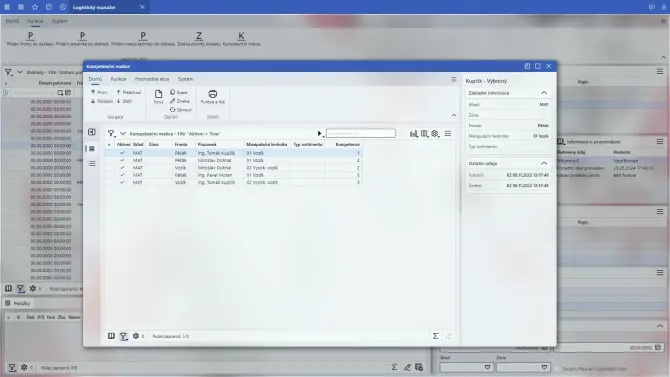

We will give you a tool to easily change priorities within the day. Depending on when the transporter arrives or according to the skills of the individual warehouse workers or the workload of the machines. In the logistics manager, there is a form in which you can see all the tasks that are ready in K2. Assign specific people or groups of people to specific tasks, as well as handling techniques.

Do you have warehouse workers in your company who can work with specific machines better than others? Or those who are not trained to handle, for example, medical goods? Prioritize according to their competencies and skills. Assign grades to both humans and machines so that the system always selects the most appropriate current human and technical manpower for the given task.

With WMS from K2, you use a native application that communicates with the system via an interface. All you need is the Chrome browser to access K2 Web. Any action is immediately prescribed to the entire system. In addition, the administrator can change the colors, layout of elements and modify the appearance of the mobile terminal according to his wishes.

K2 has created a native environment in which it communicates directly with the largest carriers within the Czech Republic. At the same time, it uses the Balíkobot aggregator, with the help of which it solves the labels itself, which are then stuck on the packages in the given warehouse. Everything from the warehouse goes to carriers and delivery services almost automatically.

Thanks to our close cooperation with the robotics masters at SLUNO, we can equip your warehouse with voice guidance. We equip each storekeeper with special headphones, thanks to which the system automatically gives him instructions by voice. You have the opportunity to use several language mutations.

Are you expanding your business? Are you planning to expand abroad? Are you planning modernization and automation in your warehouse? We will help you set up processes and propose a tailor-made solution. At the same time, we work diligently on development and bring a lot of interesting news with each version.

- Minimizing errors and the amount of dead stock in warehouse

- Efficient use of warehouses

- Easy planning and prioritization of work

- Records of all warehouse movements

- Automation using conveyors

- Warehouse operations controlled by readers

- Connection to the carrier

- Standard functions and processes

- Visualization using mobile terminals

- Logistics manager

- Prediction tools and analysis

- Data visualization and connection to BI

- Tailor-made solutions