You can rely on the information in K2

Since 2005 with K2 ERP

The extent of K2 implementation in the AWOS company

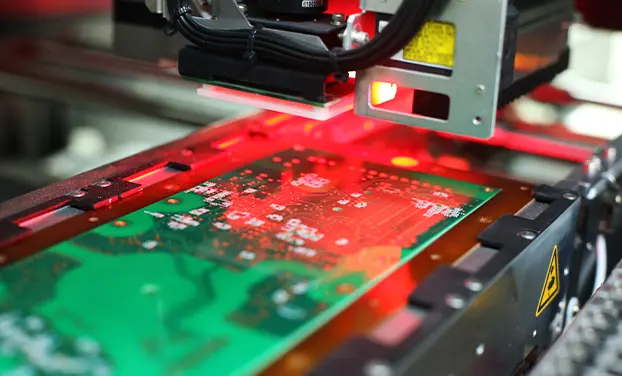

K2 ERP at AWOS manages custom production, contains definitions of bill of materials and technological procedures. The company also uses an information system for recording both quantity contracts and one-off orders. The production plan is adjusted based on customer requests for changes, which are flexibly implemented into the system even during the execution of production orders. Furthermore, thanks to the unification of requirements for the purchase of materials and components, costs are optimized. Here, the system takes into account the required delivery dates with regard to the specifics of custom production.

Interesting facts from the implementation of K2 ERP

Output of production after operations with the start-stop system.

Advanced assessment of worker productivity.

Detailed records of production numbers, serial numbers and lots.

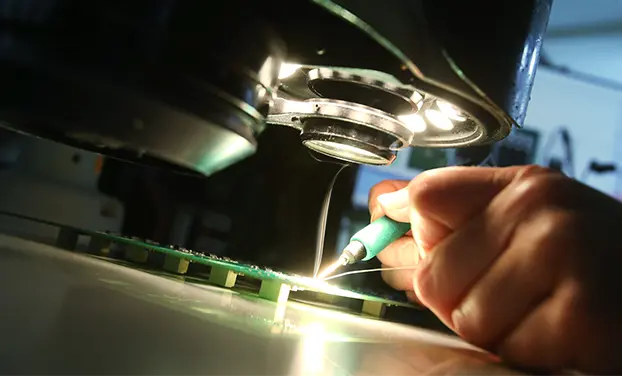

"In the area of custom manufacturing, the scope of ERP implementation is significantly influenced by the customers themselves. The effort to solve their requirements is thus also transferred to the definition of custom ERP modifications. The implementation of customer requirements at AWOS thus contributed very significantly to the controlled flow of information, which directly affects the company's success on the market."

Tomáš Koreček, Business Development Manager K2

K2 forms the backbone of all activities related to orders, from the registration of offers to the technical preparation of products and the provision of the necessary material to production planning and monitoring deadlines. Thanks to ERP, we have a very well-solved issue of full traceability and online monitoring of orders.

Lenka Šírová, managing director of AWOS s.r.o.