With K2, your customers get the data they value

The K2 information system helps Murtfeldt Plasty manage production and plan delivery dates.

The K2 information system helps Murtfeldt Plasty manage production and plan delivery dates.

22 years with the K2 IS

33 users working daily in K2

5,000 m2 production halls

€ 5.3 million annual turnover

The K2 Information System helps with managing all departments of the company. Murtfeldt Plasty not only uses production planning and management, but the K2 system in the company also manages warehouses, the purchase of materials and the ordering of shipping for individual orders. In addition, they also work with the business and marketing modules, where the ERP system of K2 not only watches over supply and demand, but also helps with tracking markets, competition, trends, and it analyzes the data collected.

The K2 Information System helps with managing all departments of the company. Murtfeldt Plasty not only uses production planning and management, but the K2 system in the company also manages warehouses, the purchase of materials and the ordering of shipping for individual orders. In addition, they also work with the business and marketing modules, where the ERP system of K2 not only watches over supply and demand, but also helps with tracking markets, competition, trends, and it analyzes the data collected.

“Murtfeldt Plasty is a manufacturing company that implemented the business, logistics and manufacturing modules of K2 IS covering the dynamic needs of their economic processes and specifics in the environment of international concern. The deployment and modifications of K2 IS are particularly focused on production planning and management. The use of technological production preparation using feedback from the evaluation of production data is very sophisticated. The planning of custom production is built on the principles of the K2 IS production modules with individualized modifications of individual parts of production processes. Business and logistics areas are dealt with effectively and efficiently with a focus on supply management and the optimization of material stocks.”

Martin Hejl, Business Development Manager K2

“The main advantage of K2 is its comprehensive range of modules that connect all departments of a business and production-oriented firm. The vendor has an online overview of not only delivery and shipping dates, but also production dates and the state of progress of the part being produced. We rely on data in K2 when dealing with customers, and they appreciate the speed and accuracy of our information. The second significant benefit is the evaluation of transparent data from K2 – e.g. scheduled and actual machining times, registering dates in processing calculations, offers or vendor activities. The greater use of K2 imposes greater responsibility on employees to do their jobs.”

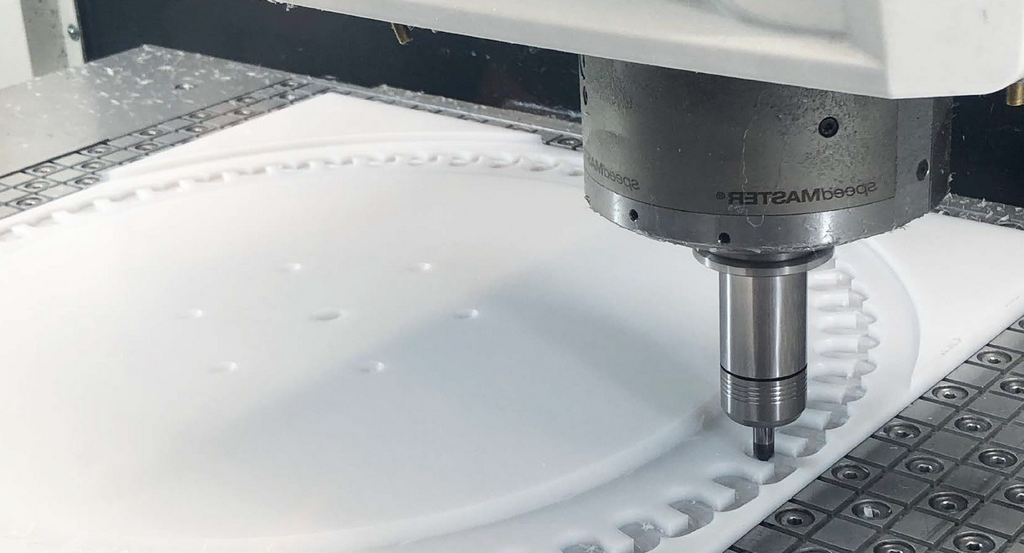

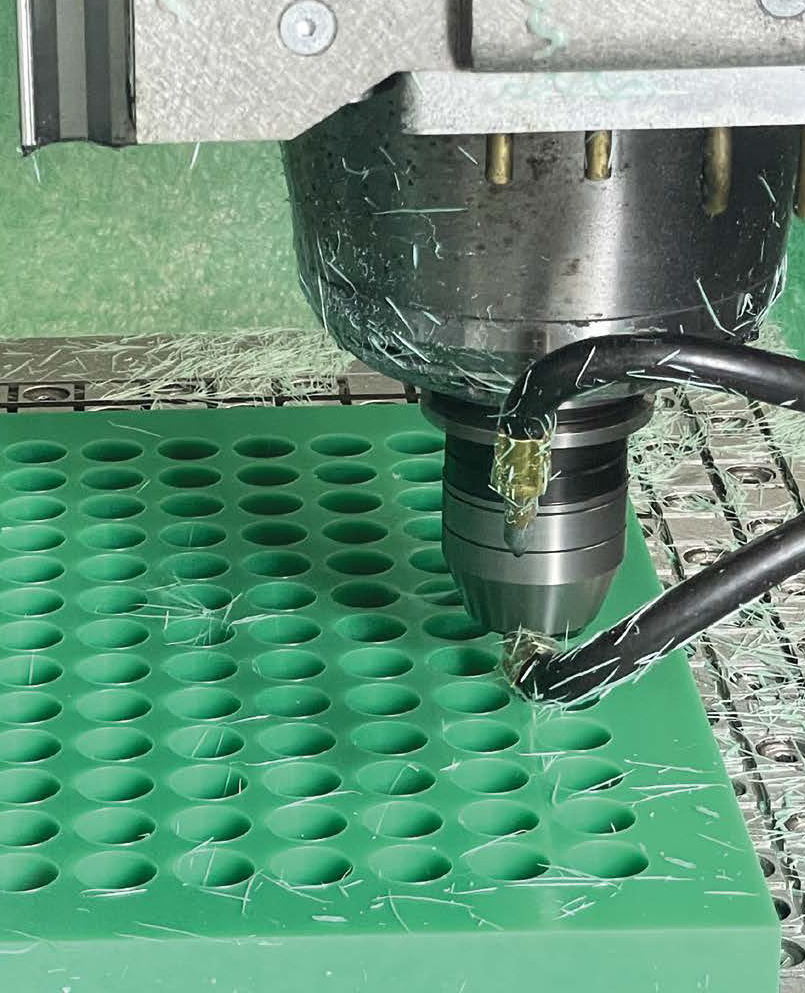

Murtfeldt Plastics is a manufacturer active on the Czech market since 1992, but the tradition of this brand goes back to the mid-1950s. Together with its Dortmund-based parent company, Murtfeldt Plastics is a worldwide manufacturer of sliding profiles, chain and belt guides, and other plastic parts for industrial use. Their transport and assembly line products made from “S” Material and its modifications are used in many industries ranging from automation technology, power units and food processing to pharmacy and laboratory technology. They have relied on the K2 Information System since 1999.