Production

Production modules in K2 offer options for complex production management of any type. Thanks to the system's robust "chassis" and the interconnectedness of the individual modules, you can solve both custom and serial production. From clear technological procedures, costing to production documents, K2 offers tools for capacity planning and implementation and reporting of work.

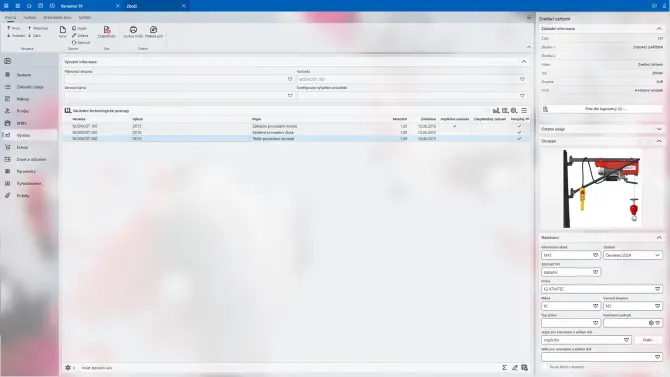

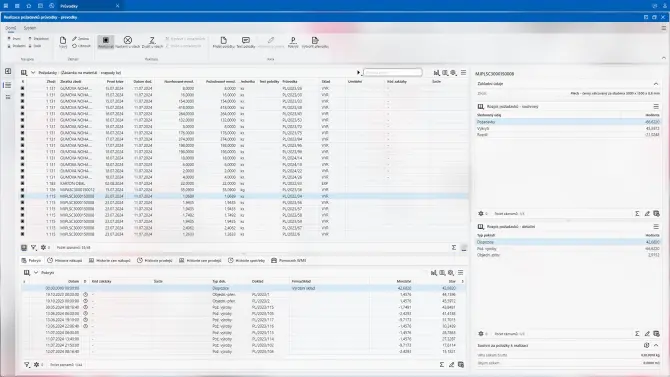

The TPP registration solution in K2 is called Multi-level variant technological procedures. The module enables the registration of production operations including several times, and a production resource is assigned to each operation – usually the machine on which the production will actually be carried out and, of course, the bill of materials, which represents consumption items, and other cost items associated with production can also be recorded here.

You will appreciate that the production technology and the bill of materials itself are also available in a clear tree structure, which allows you to browse all levels and subordinate semi-finished products. Individual parts of the TPP can be approved in K2, and with the use of K2 workflow, production processes are fully managed and under control.

.webp?w=670)

For each product or semi-finished product, there may be several variants of production procedures, where at least one is always the default. Variants can have a defined validity and method of use – for example, production batch, cooperation and many others.

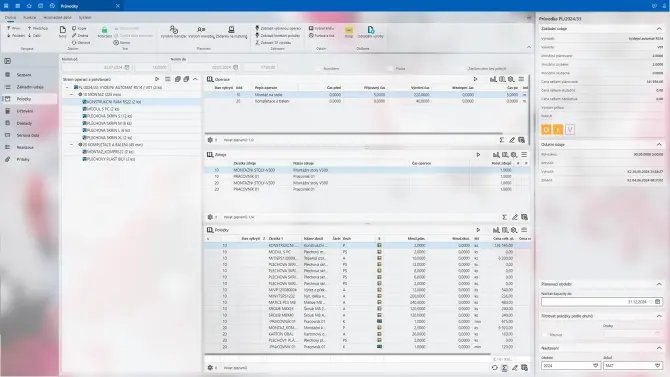

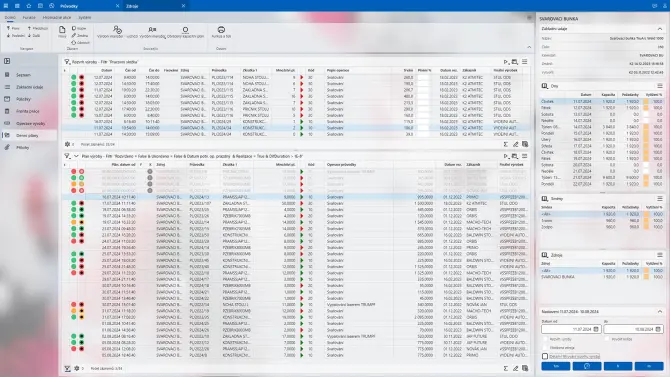

On the basis of TPP and through the Production Manager tool, production documents (job card) are generated in K2. These documents are essentially a picture of the production process and represent a production instruction and form a work queue for specific people or machines. The production manager also plans capacity for a specific date and time, and thanks to the items in the parts list, requirements for the purchase and partial production of semi-finished products arise. This job card is also used for production implementation, where production workers report their work and thus record the produced pieces in the system and at the same time record the exact consumption of input materials and semi-finished products and the actual times of production operations.

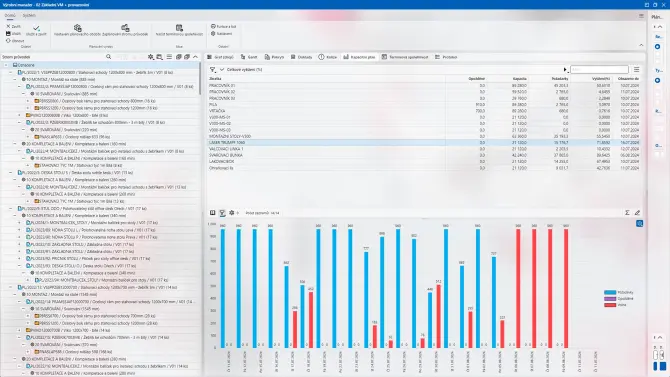

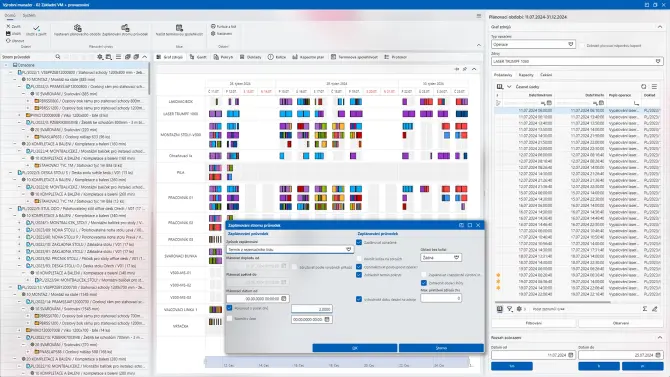

For production planning, a tool called the Production Manager is available in K2, which plans capacity jobcards according to prescribed resources, their production calendars and standards in operations. In K2, you can plan forward from a certain date or backward to a certain date. Alternatively, you can use the customer's desired dates and plan production back to these dates.

Planning and rescheduling of production can also be implemented in K2 through planned tasks, when the parameters for planning are defined in advance and this action runs on the server at night. It is suitable for larger production companies, where there is a larger amount of production documents.

In addition to automatic production planning, K2 offers a tool for workshop scheduling, i.e. manual specification of individual operations and jobcards. It is a superstructure over the production plan, and it really serves to specify a specific production plan for the following days and weeks. This tool is suitable, as the name implies, for the management of one specific workshop and is most often used by Masters of the given workshops. It is scheduled for weeks, days and shifts and the exact sequence of production operations on specific resources is determined.

K2 can also take into account the material coverage of future production when planning production trees. The production plan is then displayed via a Gantt chart by individual resources on the timeline. The production manager tool also offers additional information on material coverage, the capacity plan and utilization of individual resources in the future or, for example, a comprehensive breakdown of products and semi-finished products within the loaded production tree. At the same time, the Production Manager offers an insight into the fulfillment of promised deadlines.

Supplying production in the required quantity and time is not easy. The "Just In Time" principle is difficult to follow even from the point of view of meeting the order deadlines. The mathematical model in the K2 system takes this into account when planning production and offers a sophisticated but at the same time simple tool for production supply. The material request goes through the production documents and finds out which materials are missing or will be missing. It is on the basis of the coverage function that this mechanism calculates exactly when, how much and what kind of material the production will need. A similar mechanism is also used in purchasing during production planning.

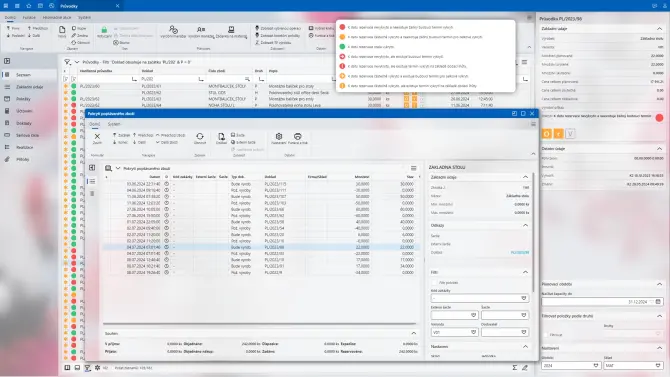

The Production Logging tool allows production workers to report their work and thus record the fact from operation back into the system. In this way, K2 receives a record of the production of the given product in a specific quantity and the actual time of the production operation. During the so-called withdrawal of production, there is an immediate consumption of input materials and semi-finished products or the creation of a batch of products for storage. The tool also allows individual production events to be recorded, typically the start, stop and end of production in real time.

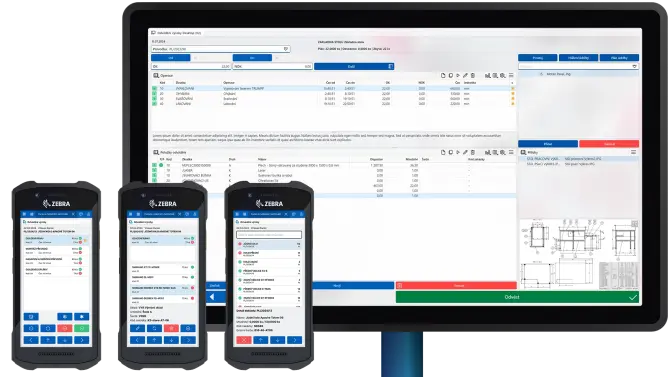

By default, in K2 there are 3 basic display modes for the production completion tool:

- Touch tablet, where the control is adapted for touch on a larger screen.

- Mobile terminal, typically a mobile phone-sized device with a reader.

- Desktop, where control takes place using a mouse and keyboard.

In general, this is the main output from the system that all production workers work with on a daily basis. Thanks to the withdrawal terminals, completely paperless production can be introduced in the company. In addition to the work queue, these terminals also offer other options related to the production of the given products – such as drawings and production procedures, but also functions for example for reporting maintenance, recording a break or overhead operations such as inspection, adjustment etc.

For the compilation of Calculations, there is a separate data module called Calculations in K2, which, based on pre-defined calculation formulas and technological procedures, compiles a comprehensive, clear and above all unique document on the calculation of the calculation for the given day. On the Calculation document, input items are summarized by individual category, while detailed breakdowns of specific items, their quantities and prices are also available. The prices are taken into account both for the calculation dose and for the unit. Costing can be created from anywhere in K2, not only for products and semi-finished products, but also for entire orders, including items such as transport and other services.

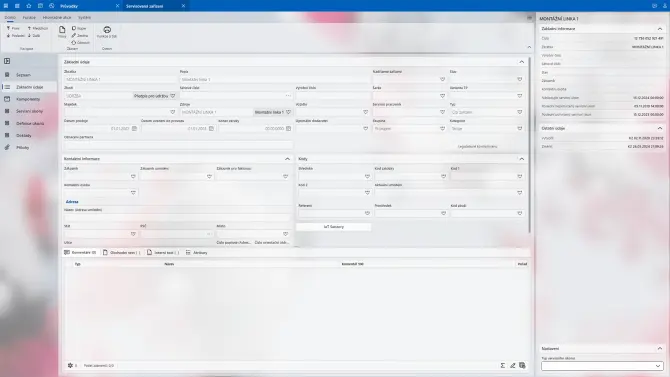

In K2 you will also find a module for managing maintenance and service activities. This module is connected with sales, purchases and production and from a record point of view it is linked with the Property, Vehicle records and Production Resources modules. Each device is registered in K2 and it is possible to collect requirements from the field or operation for their maintenance and service. K2 also offers the possibility to plan service interventions in advance.

The connection with production modules affects shutdowns and capacity planning of production resources. The schedule of maintenance and service actions is usually displayed in a simple table of scheduled service actions or in a calendar. Whether from a calendar or spreadsheet, on a mobile phone or laptop, at work or at home, a service technician or maintenance worker can carry out a given task, report their activity and record online material consumption, just like in production.

Thanks to the planning of service actions and simple implementation, K2 offers a highly comprehensive tool for managing maintenance and service.

- Comprehensive production management

- Serial and custom production

- Technical production preparation (TPP)

- Job card

- Production manager

- Production planning

- Completition of production

- Communication with third-party systems

- Support from K2 consultants

K2 offers highly comprehensive modules for manufacturing and related tools that you can use to manage any manufacturing business. From furniture and construction elements, where every screw and nut is solved, through heavy industry and automotive, where a high emphasis is placed on precision, to the pharmaceutical industry, where quality and traceability are key.

K2 enables manufacturing companies to plan and perform preventive maintenance on machines. For example, a company in the food industry can set regular inspection intervals for cleaning and maintenance operations on production lines. This reduces the risk of unplanned outages and increases equipment reliability.

Using the planning mechanisms in K2 and the experience of planners, K2 creates an environment and a tool for creating meaningful production plans that maximize the use of expensive production resources. We know from experience that, in the end, it is not only a question of capacity utilization, but of finding an acceptable compromise between efficiency and reliability.